Successful operations don't happen by accident. When the job goes exactly to plan - when we find a proven way that works - we document everything. Proven, consistent results are what you need, so that's what SPM™ provides.

A Permian operator wanted to optimize the maintenance—and associated costs—of its frac equipment and consumables. SPM Oil & Gas proposed a field trial with SPM™ EdgeX Carbide Seats across three sites. The operator ran the engineered carbide seats an average of 655 hours—more than 8X longer than previous seats. One seat lasted 760 hours, setting a record for the longest life of an SPM EdgeX Carbide Seat in North America.

Learn MoreA Permian operator wanted to optimize the maintenance—and associated costs—of its frac equipment and consumables. SPM Oil & Gas proposed a field trial with SPM™ EdgeX Carbide Seats across three sites. The operator ran the engineered carbide seats an average of 655 hours—more than 8X longer than previous seats. One seat lasted 760 hours, setting a record for the longest life of an SPM EdgeX Carbide Seat in North America.

Learn MoreSimplified frac site helps reduce NPT and HSE risks

Learn MoreThe resource-rich Permian Basin is one of the most active plays in North America. Unlike other shale plays, the Permian has greater geologic complexity, which can put increased pressure on equipment and increase consumables costs.

Learn MoreA premier operator that operates 1,000’s of wellheads in the Utica Basin and has named SPM Oil & Gas (SPM) as its sole wellhead provider.

Learn MoreImproves on site efficiency and cost

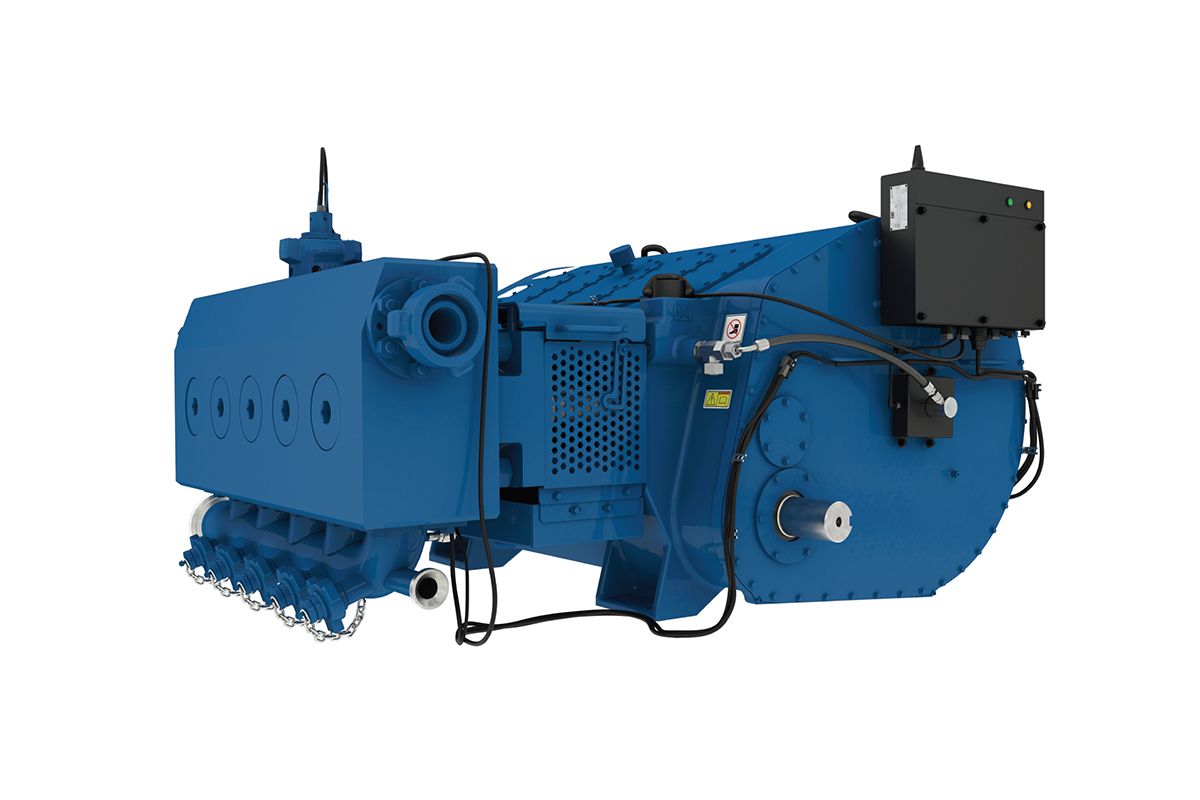

Learn MoreDowntime and non-productive time (NPT) are the enemies of pressure pumping companies across every basin. Conventional frac pumps can crack as companies push equipment to near-continuous duty, increasing capital and operating expenses. SPM™ Oil & Gas engineers designed the SPM™ WS 335 Frac Pump to eliminate a leading cause of pump failure and resulting NPT to meet companies’ uptime demands.

Learn MoreEfficiency is always top of mind in the oil and gas industry, but how do companies achieve maximum efficiencies? By using innovative solutions to transform the performance and longevity of their pump consumable parts. The SPM™ EdgeX Carbide Seat’s innovative design supports pressure pumpers’ continuous pursuit of reduced downtime and costs to meet the demands of the field and workforce.

Learn MoreThe SPM™ Oil & Gas Fort Worth Service Center holds the distinction of being the Pump Center of Excellence in the SPM Edge Service Center network, which ensures the Fort Worth service team is at the forefront of pressure pumping advancements and knowledge.

Learn MoreThe high-performance SPM EdgeX Valve and EdgeX Carbide Seat are built to withstand the wear-and-tear of today’s pumping conditions.

Learn More