THE FACTS

4,500 tons of proppant pumped in 24 hours

18m3/minute pump rate

48 hours rig up time

Just over 2 days of frac time

TOTAL SAVINGS

$1,000,000 in pump time

$640,000 in replacement costs

$160,000 in repair costs

When another service provider failed to deliver Hammerhead Resources’ ambitious 18 m3 /minute pumping targets, the operator partnered with SPM™ Oil and Gas (SPM), for frac equipment services. The 15,000-psi Seaboard™ One Straight Line (OSL) Frac Connection helped Hammerhead simplify its rig site and reduce risk while breaking industry records for tonnage pumped in 24 hours.

With more than 200,000 net acres in each of the Montney and Duvernay Formations, our customer is continually looking for innovative, new ways to optimize its hydraulic fracturing operations. To maximize completion efficiency, the operator sought a pump rate of 18 m3 /min. After another service provider failed to deliver this high pump rate, SPM™ was hired, to provide frac connection technology for a total of 12 wells across two pads in the Montney Shale.

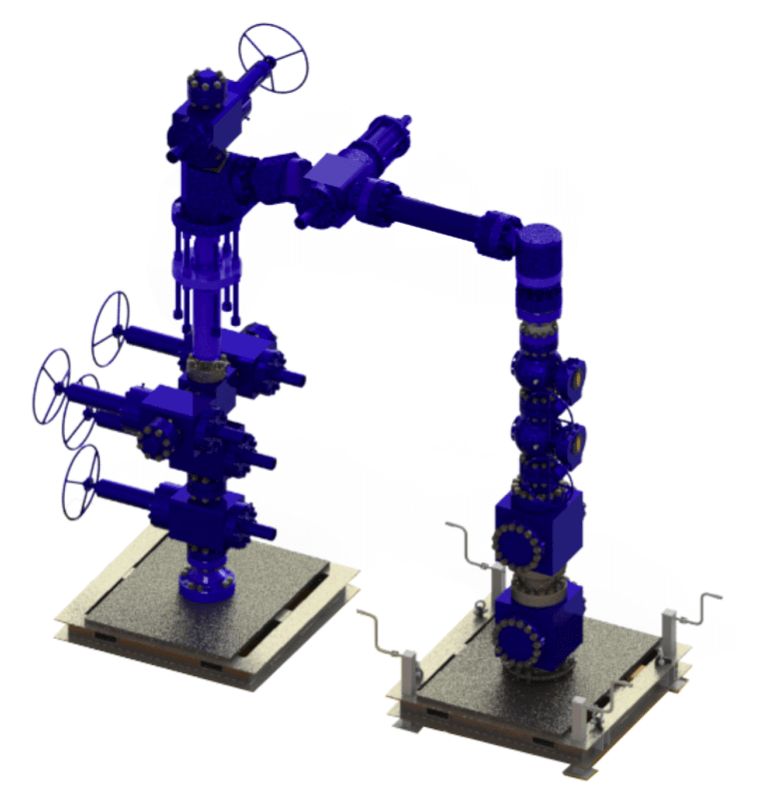

SPM™ recommended the 15,000-psi Seaboard™ One Straight Line (OSL) Frac Connection—and worked around the clock to deploy and rig it up within 48 hours. Computational flow dynamics (CFD) simulations and predictive erosion studies helped SPM™ and the operator identify and mitigate potential hazards. Throughout the campaign, SPM™ provided proactive erosion monitoring and equipment inspections without impacting other operations. A second SPM™ crew helped the operator meet its aggressive pumping targets as scheduled.

On the first multi-well pad, the operator placed 4,500 to 9,000 tons of proppant per well at pump rates ranging from 14.5 to 18 m3 /minute—setting new records for tonnage pumped within 24 hours in North America. The SPM™’s team applied lessons learned to optimize wells during the next stimulation job. On the second pad, they cut average frac time per well from 6 days to just over 2 days and placed up to 7,500 tons of proppant per well with minimal erosion. In addition to enabling the operator’s ambitious pump rates, the innovative frac connection helped the operator simplify its frac site and reduce health, safety, and environment (HSE) risk. The OSL Frac Connection reduced rig-up time by approximately 71% compared with previous configurations, saving approximately $1 million. Mitigating erosion helped them prolong equipment life and save an estimated $800,000 in repair and replacement costs. As a result of this successful campaign, SPM™ was named their preferred frac equipment provider for the next three years.

Engineered for demanding frac applications, the patentpending Seaboard™ One Straight Line Frac Connection significantly reduces the amount of iron and connections required on the wellsite. This means a corresponding reduction in nonproductive time (NPT), rig-up time, labor costs, potential leak paths, and safety hazards.

Related Case Studies

-

Achieves Zero Lost-Time Injuries, Breaks Annual Safety Record

Simplified frac site helps reduce NPT and HSE risks

Learn More -

SPM™ Seaboard™ Offline Cementing

Improves on site efficiency and cost

Learn More -

SPM™ Seaboard™ Unitized Lock-Ring Improves Safety and Saves Cost

A premier operator that operates 1,000’s of wellheads in the Utica Basin and has named SPM Oil & Gas (SPM) as its sole wellhead provider.

Learn More

Latest News

-

KOP™ AM20 SERIES GATE VALVES

Learn More -

Caterpillar Acquired Weir Oil & Gas, Launched SPM Oil & Gas

Learn More -

Celebrating Manufacturing Month

Learn More -

Janelle Harre Recognized in Oil and Gas Investor’s 2022 “25 Influential Women In Energy”

Learn More -

Meet SPM Women in Engineering

Learn More -

OPITO-Accredited Iraq Apprenticeship Training

Learn More