TOTAL SAVINGS

Decreased erosion by approximately 70%

Replaced six flow lines between the frav manifold and the wellhead

Achieved zero lost-time injuries (LTIs)

The operator actively explores and develops unconventional reserves throughout the Western Canadian Sedimentary Basin, primarily focusing on the gas- and condensate-rich Montney Formation. With reserves estimated at 449 Tcf, the Montney formation is among the world’s largest natural gas plays. To produce it, operators must use innovative technologies—such as multiwell pad operations, directional drilling, and multistage hydraulic fracturing—to maximize efficiency and develop these wells in a way that is safe, economical, and sustainable

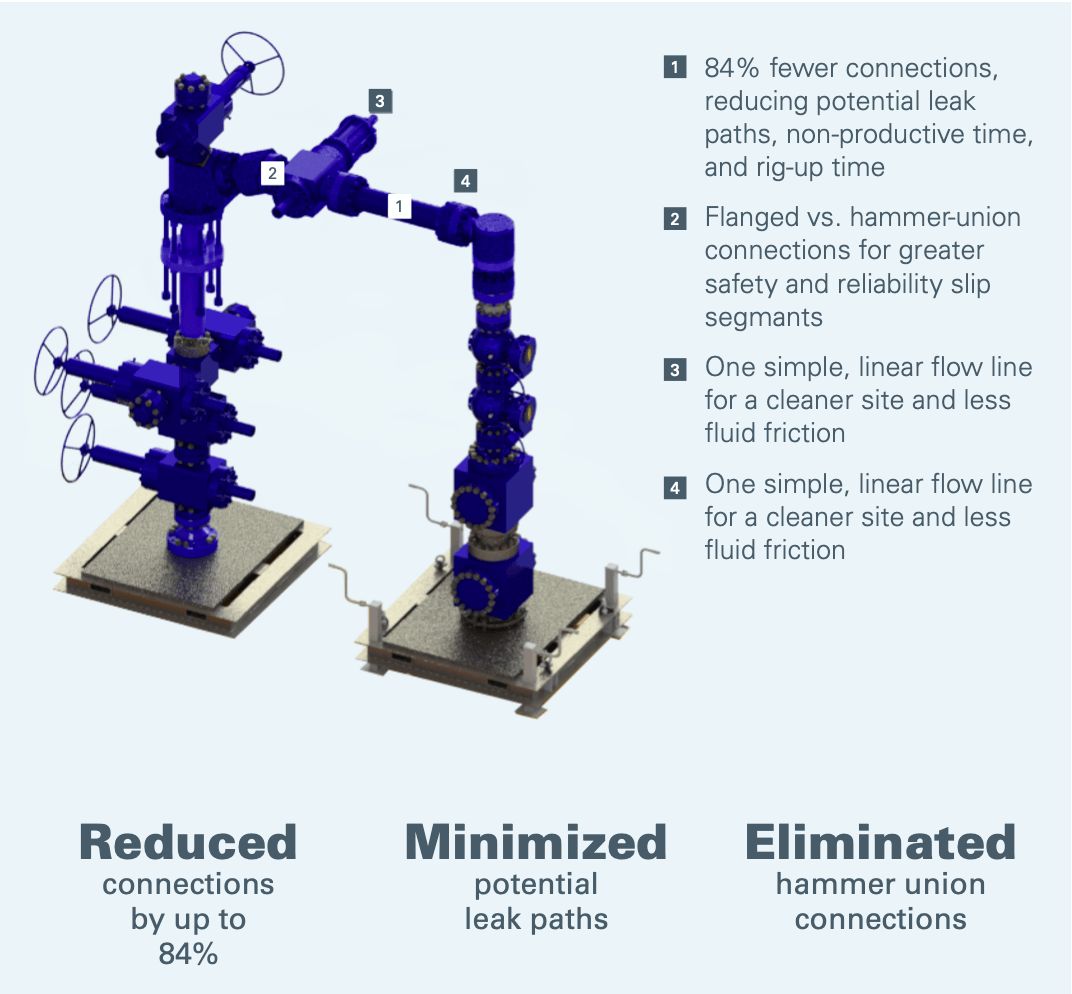

To help the operator save time and reduce operational risk, SPM™ Oil & Gas (SPM), their sole wellhead partner, approached the operator about using the SPM™ Seaboard™ One Straight Line (OSL) Frac Connection. The OSL Frac Connection replaces hammer union connections with flanges, dramatically reducing the amount of iron and connections required on the wellsite. Instead of six flow lines between the frac manifold and the wellhead, the innovative frac connection features just one simple, large-bore connection—for faster rig-up time and fewer safety risks.

Prior to starting the job, SPM engineers debriefed the company and conducted rigorous computational fluid dynamics (CFD) simulations to predict erosion. The results helped NuVista minimize erosion and prolong frac equipment life.

The operator deployed the OSL Frac Connection on an eight-well pad. SPM mobilized and rigged up the new frac connection within 48 hours—saving approximately $63,000 and five days of setup time compared to a traditional hammer union configuration. Today, they routinely uses the OSL Frac Connection to pump more than 5,000 tons of proppant per well.

This move helped the operator set a new record in safety. For the first year in the company’s history, they achieved zero lost-time injuries, including employees and contractors. The Canadian operator recognized SPM for its contribution to this exemplary achievement and its ongoing commitment to communication, safety, and environmental protection.

Engineered for demanding frac applications, the patent-pending SPM Seaboard One Straight Line Frac Connection significantly reduces the amount of iron and connections required on the wellsite. This means a corresponding reduction in nonproductive time (NPT), rig-up time, labor costs, potential leak paths, and safety hazards.

RELATED CASE STUDIES

LATEST NEWS

-

Saving NPT in Extreme Conditions

Oilfield companies require pressure pumping equipment that meets today’s rigorous demands and are paying closer attention to the longevity of parts on site. One of the top consumables, fluid ends, can directly impact the uptime of hydraulic fracturing pumps and support operational efficiency.

Learn More -

SPM™ WS 335 Frac Pump Surpasses 13,000 Pumping Hours in the Permian

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today an SPM™ WS 335 Frac Pump achieved more than 13,000 pumping hours in the Permian before its first overhaul.

Learn More -

Fluid Ends Engineered for the Oilfield Deliver a Competitive Advantage

Well services equipment must endure the toughest environments. Pressure pumping operators need reliable solutions and know their fleet is only as strong as its most sensitive components. Critical pump consumables such as fluid ends must be built to last no matter the operating conditions.

Learn More -

SPM™ Oil & Gas Launches On-Demand Oilfield Parts Availability in North America

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today a new streamlined platform to provide drilling and production expendables to customers and distributors. Oilfield parts can now be ordered on-demand across North America.

Learn More