Case Study

CUSTOMER:

Trican

LOCATION:

Canada

PRODUCTS:

SPM™ Large Bore, SPM QEM 3000, SPM EdgeX Carbide Seat, Cat® 3512E DGB T4, Cat TH55-E90

INDUSTRY:

Oil & Gas

APPLICATION:

Well Services

SOLUTION:

Comprehensive sitewide solution including SPM’s high-performance frac pump and pump consumables as well as frac iron alongside Cat DGB T4 and transmission

DUAL-FUEL TECHNOLOGY PAIRED WITH HIGH-PERFORMANCE PUMPS, CONSUMABLES AND TRANSMISSIONS LOWER FUEL COSTS AND ENHANCE PERFORMANCE

A Total Site Solution for the Harshest Environments

Trican takes advantage of Caterpillar’s advanced equipment and technology to enhance performance and reduce fuel costs.

Cutting Fuel Spend While Optimizing Efficiency

As a full-service provider of Cementing, Coiled Tubing and Hydraulic Fracturing Services, Trican Well Service Ltd. is committed to investing in new and integrated solutions that can help increase operational efficiency and support climate-related objectives. The Company strives to pump more each day without increasing cost and is proactively using natural gas to curb diesel consumption and reduce greenhouse gas (GHG) emissions.

Fuel efficiency and on-site availability are especially important given the remote locations and brutal below-zero temperatures in British Columbia and Alberta where the company operates. With these challenges in mind, Caterpillar Oil & Gas has helped enable Trican to continuously modernize operations and embrace alternative fuel sources while maintaining reliable performance in harsh operating conditions.

To improve operational efficiencies, Trican required a comprehensive site solution that would maximize uptime, optimize wellsite performance and displace higher-cost diesel. Trican collaborated with Caterpillar Oil & Gas to develop an advanced comprehensive solution aligned with the company’s full-service approach to the oilfield.

Fueling Growth While Lowering Costs

For more than 30 years, Trican has trusted Cat and SPM technologies and services to support pressure pumping operations in challenging conditions and implement technology upgrades that support climate-related targets.

Trican was the first to trial the Cat 3512E Dynamic Gas Blending™ (DGB) engine in its region and has since deployed more than 75 3512E DGB T4 engines across its fleet, making it the largest lower-emissions fracturing fleet in Canada.

“As the cost of natural gas is significantly less than diesel, Cat DGB technology helps us substantially lower fuel spend, ensures a ready fuel source on-site and supports our transition to natural gas as the Company’s primary fuel,” said Trican’s Vice President, Fracturing, Jim Rukin.

“DGB technology is fueling growth without the cost,” added Trican’s Hydraulic Fracturing Division Manager, Ty Sutherland. “We used to bring 30,000 liters of fuel to a site each day, and now we do that every three days. We’ve also seen increased pump times and efficiency from integrating our Cat engines and SPM pumping technologies.”

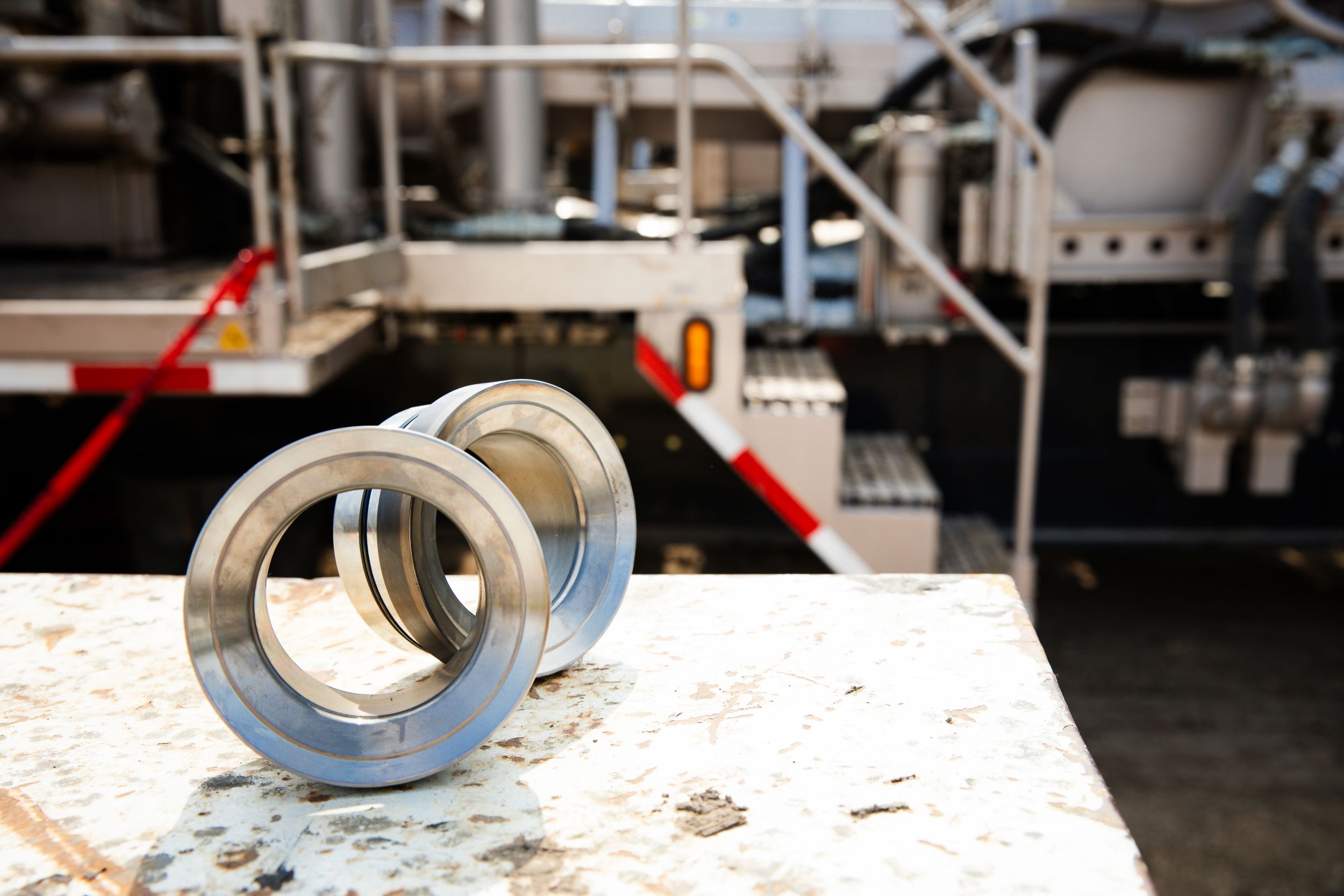

In addition to the Cat 3512E DGB T4 engine, Trican also operates the Cat TH55-E90 transmission in its pressure pumping operations. It’s the company’s transmission of choice due to its smaller footprint and ability to run 20,000 to 25,000 hours before requiring an overhaul. The Company also uses several SPM technologies in the field including the QEM 3000 pump. To further enhance operational efficiency from pump to wellhead, the company was the first in Canada to utilize the SPM Large Bore to eliminate excess iron and reduce rig-up time. Trican also uses the high-performance pump consumable SPM EdgeX carbide seats throughout its pump portfolio for extended service life, reduced non-productive time (NPT) and lower operating costs.

CONSISTENT, FULL-SERVICE APPROACH

Trican continues to experience long-term benefits resulting from the application of both Cat and SPM innovations working seamlessly as a sitewide solution for consistent durability, efficiency and longevity in the field.

Cat DGB technology has achieved an average diesel displacement rate of up to 70%, with up to 85% peak diesel displacement under certain operating conditions. This important fuel flexibility has helped Trican decrease its diesel consumption and operating costs in addition to supporting the company’s GHG emissions reduction goals. The DGB engine also enables the well services company to operate near continuous duty under the harshest operating conditions. Combined with 3,000-horsepower capacity QEM pumps capable of withstanding high pressures ranging from 12,000 to 13,000 psi, operators have extreme confidence in Trican’s systematic approach to achieving operational excellence.

Seal wear and end-of-life events for components not only increased operating and maintenance costs but also reduced pumping hours, which ultimately impacted the bottom line.

POISED TO MEET ENERGY DEMANDS TODAY AND TOMORROW

Keeping pace with the oil and gas industry’s changes requires a relentless commitment to innovation and continuous improvement. Utilizing solutions that are purpose-built for demanding conditions provides the rugged durability and operational efficiency Trican requires to continuously optimize costs and support climate-related objectives.

“Using a broad range of Cat and SPM solutions enables us to lower fuel consumption and costs without sacrificing high performance, so we can continue to meet growing global energy demands as the industry evolves,” said Trican’s Chief Operating Officer, Todd Thue.

1 Trican Well Services. https://tricanwellservice.com/trican-deploys-canadas-first-low-emissions-fracturing-fleet/

Related Case Studies

-

SPM™ EdgeX Valve and Carbide Seat

SPM™ EdgeX Valve and Carbide Seats ran a record-breaking 515 hours—a 540% increase compared to previous seats— dramatically increasing oilfield safety and nonproductive time.

Learn More -

SPM™ EdgeX Valve and Carbide Seat - Permian Basin

The resource-rich Permian Basin is one of the most active plays in North America. Unlike other shale plays, the Permian has greater geologic complexity, which can put increased pressure on equipment and increase consumables costs.

Learn More -

SPM™ EdgeX Valve and Carbide Seat - 760 Hours of Seat Life in the Permian

A Permian operator wanted to optimize the maintenance—and associated costs—of its frac equipment and consumables. SPM Oil & Gas proposed a field trial with SPM™ EdgeX Carbide Seats across three sites. The operator ran the engineered carbide seats an average of 655 hours—more than 8X longer than previous seats. One seat lasted 760 hours, setting a record for the longest life of an SPM EdgeX Carbide Seat in North America.

Learn More

Latest News

-

Caterpillar Acquired Weir Oil & Gas, Launched SPM Oil & Gas

Learn More -

KOP™ AM20 SERIES GATE VALVES

Learn More -

Janelle Harre Recognized in Oil and Gas Investor’s 2022 “25 Influential Women In Energy”

Learn More -

SPM™ Oil & Gas Launches On-Demand Oilfield Parts Availability in North America

Learn More