At A Glance

Increases seat life by 6X and valve life by 2X compared to conventional seats and valves

Replaceable in the field

Compatible with any tapered fluid end

Resists shattering

Improves safety

Reduces NPT

The Facts

540% increase in seat life

100% increase in valve life

-20° C to -4° C operating conditions

The Innovation

An oilfield services provider in Western Canada subjects its fracking equipment to some of the most challenging conditions that exist in the industry. It routinely pumps high volumes of proppant at pressures up to 12,500 psi during harsh winter operations (–20 °C | –4 °F). Standard seats typically have an average life of 80 hours. During a three-month field trial with the SPM™ EdgeX Valves and Carbide Seat, the engineered seats ran a record-breaking 515 hours—a 540% increase compared to previous seats—and valve life doubled compared to previous valves, dramatically increasing safety and reducing nonproductive time (NPT).

The Challenge

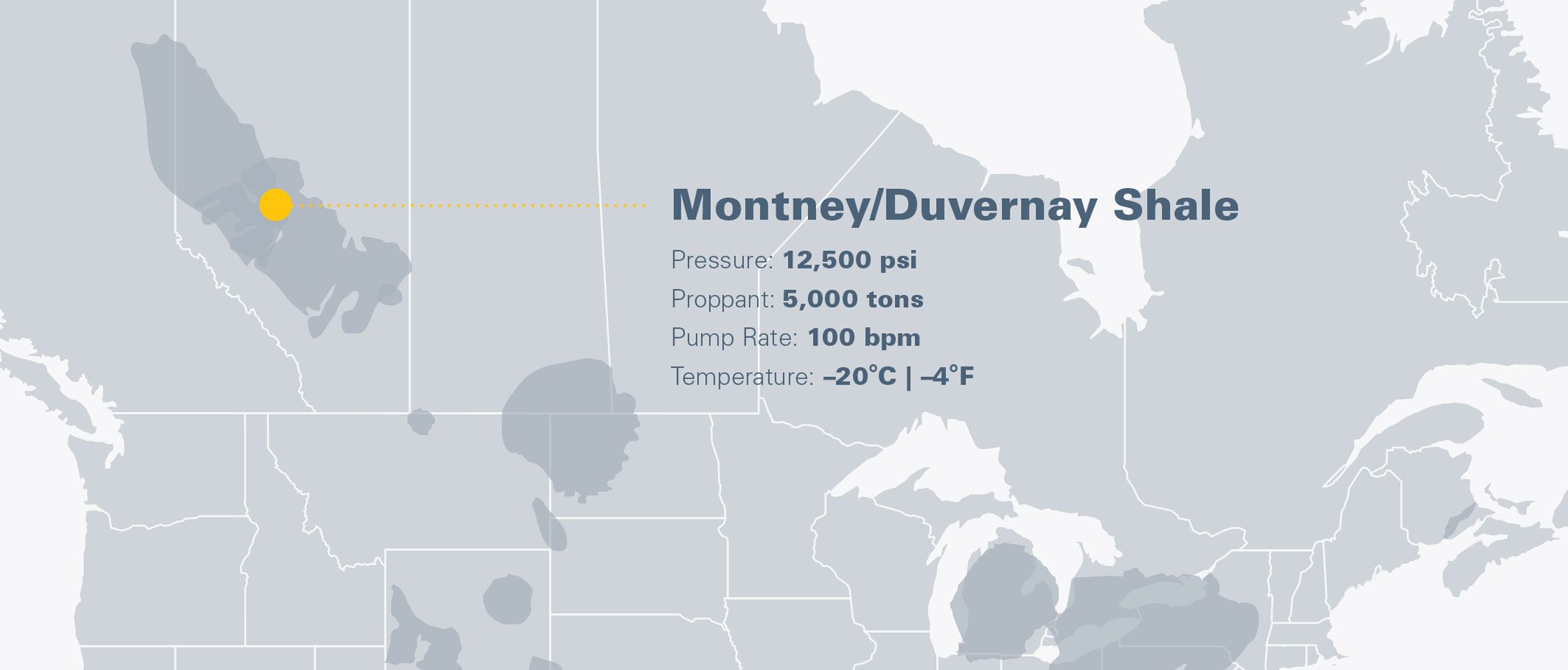

The Montney and Duvernay plays in Canada subject hydraulic fracturing equipment to some of the most challenging fracing environments there are due to high pressures, high proppant volumes and extreme winter temperatures, ranging from –5 to –15°C (23 to –4°F). These unforgiving conditions prevent the use of less-durable fracking equipment and components.

An oilfield services provider operates pumps in both shale plays and wanted to carve out greater efficiencies to further streamline their multi-well pad operations and reduce their NPT. Pulling valves and seats is the most labor-intensive part of fluid-end maintenance, increasing NPT when fluid ends are offline. While 80 hours is a typical life span, the company was eager to extend maintenance intervals and eliminate seat replacement and maintenance on the pad.

Pumping 2°C (36°F) water in –20°C (–4°F) weather has been known to cause tungsten carbide fluid-end seats to become brittle or shatter, increasing consumables and labor costs. Additionally, the oilfield service provider pumped 5,000 tons of sand rather than the typical 1,200–1,400 tons of sand used in offset wells, subjecting their seats and valves to significantly more erosion.

The Approach

SPM Oil & Gas proposed a three-month field comparison, monitoring the SPM EdgeX Carbide Seats and EdgeX Valves to track their performance against conventional pump expendables on a single pump. The operating conditions of the testing sites were 12,500 psi, 350 tons of sand/stage, produced water, 100 bpm and temperatures well below freezing (–20°C | –4°F). The SPM Edge Engineering Field Assist Team supervised the test, checking sets at regular maintenance intervals and comparing them for wear.

The Result

The SPM EdgeX Carbide Seats produced dramatic results for the oilfield services provider. Unlike tungsten carbide seats which can become brittle or shatter in cold weather, the SPM EdgeX Carbide Seats were unaffected by the cold temperatures and lasted 6x longer than the previously used seats.

SPM Oil & Gas ran the SPM EdgeX Carbide Seats a record-breaking 515 hours compared to the 80-hour average life span of conventional seats—increasing seat life approximately 540%. In fact, the operator finished the job before the seats could be run to failure, which gave the crew confidence that the new SPM EdgeX Carbide Seats may last even longer.

Additionally, the SPM EdgeX Valves lasted 120 hours. This was a 100% increase in valve life, as the previously used valves lasted 60 hours.

Based on this successful field trial, the operator immediately ordered SPM EdgeX Carbide Seats and EdgeX Valves to outfit their fleet. These components eliminated the need to pull seats on-site, leading to longer pumping time, reduced maintenance and increased satisfaction.

The Solution

SPM Oil & Gas’ patented SPM EdgeX Carbide Seat and EdgeX Valve set a new industry standard by increasing seat life 6X compared to conventional seats, which typically last an average of 80 hours, and doubling valve seat life compared to conventional valves. It is a timely solution for operators focused on pump utilization and reduced downtime for pump maintenance. Engineered with the entire fracking site in mind, the SPM EdgeX Carbide Seat and EdgeX Valve enable operators to push their fleets harder while significantly reducing maintenance time and costs for seats and valves. This dramatic increase in longevity enables operators to reduce the amount of time pulling seats on-site while reducing expenses for a costly consumable.

The SPM EdgeX Carbide Seat offers greater resistance to wear, cracking and washout, even with large particles. It fits any standard taper fluid end and eliminates sensitivity to installation errors, due to its strategic design and placement of tungsten carbide and steel. Additionally, it can be replaced in the field with standard tooling.

The SPM EdgeX Valve features a patented and proprietary engineered design that optimizes its performance when used with the SPM EdgeX Carbide Seat—to wear deeper and last twice as long as standard valves without failure risk. Its material and heat-treated combination provide exceptional erosion resistance and durability, as well as high sand-abrasion resistance with every stroke. Its standard 30° strike angle maximizes interchangeability, while its unique leg design ensures stability through all operating conditions, including high lift.

RELATED CASE STUDIES

LATEST NEWS

-

Saving NPT in Extreme Conditions

Oilfield companies require pressure pumping equipment that meets today’s rigorous demands and are paying closer attention to the longevity of parts on site. One of the top consumables, fluid ends, can directly impact the uptime of hydraulic fracturing pumps and support operational efficiency.

Learn More -

SPM™ WS 335 Frac Pump Surpasses 13,000 Pumping Hours in the Permian

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today an SPM™ WS 335 Frac Pump achieved more than 13,000 pumping hours in the Permian before its first overhaul.

Learn More -

Fluid Ends Engineered for the Oilfield Deliver a Competitive Advantage

Well services equipment must endure the toughest environments. Pressure pumping operators need reliable solutions and know their fleet is only as strong as its most sensitive components. Critical pump consumables such as fluid ends must be built to last no matter the operating conditions.

Learn More -

SPM™ Oil & Gas Launches On-Demand Oilfield Parts Availability in North America

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today a new streamlined platform to provide drilling and production expendables to customers and distributors. Oilfield parts can now be ordered on-demand across North America.

Learn More