AT A GLANCE

Eliminated field replacements

Reinforeced the key wear area with tungsten carbide

Enabled compatibility with any tapered fluid end

Resisted shattering

Reduced safety risks and unplanned downtime

THE FACTS

One seat ran 760 hours

8x longer seat life

Zero on-site seat maintenance

A Permian operator wanted to optimize the maintenance—and associated costs—of its frac equipment and consumables. SPM™ Oil & Gas proposed a field trial with SPM™ EdgeX Carbide Seats across three sites. The operator ran the engineered carbide seats an average of 655 hours—more than 8X longer than previous seats. One seat lasted 760 hours, setting a record for the longest life of an SPM™ EdgeX Carbide Seat in North America.

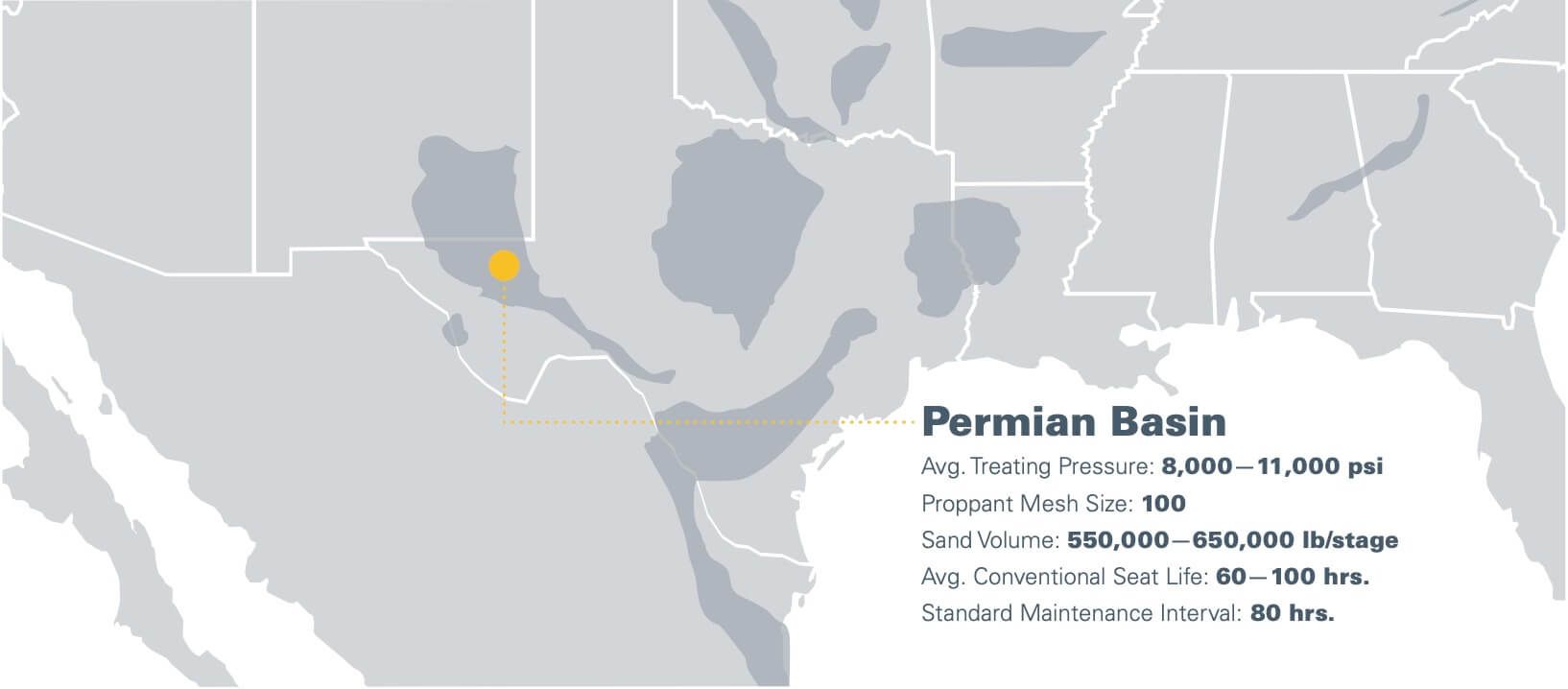

The resource-rich Permian Basin is one of the most active plays in North America. Unlike other shale plays, the Permian has greater geologic complexity, which can put increased pressure on equipment and increase consumables costs.

An oilfield services provider operating pumps in the Permian wanted to improve operational efficiencies on its multiwell pads by reducing maintenance expenses and nonproductive time (NPT). When pumping 550,000 to 650,000 pounds of 100-mesh sand per stage at 8,000 to 11,000 psi, standard steel seats were only lasting 60 to 100 hours. The company was replacing seats every 80 hours, resulting in high materials and labor costs. To maximize operational efficiency and improve worksite safety, it was looking for a way to stop pulling seats on the field.

SPM™ Oil & Gas’ team recommended using SPM™ EdgeX Carbide Seats, which offer greater resistance to wear, cracking, and washout—even with large particles. Extensive lab and field testing showed an average of six times longer life than conventional steel seats. The carbide-reinforced seats were designed to protect high-wear areas while fitting with the customer’s standard taper fluid ends and eliminating sensitivity to installation errors.

The SPM™ EdgeX Carbide Seat produced substantial results for the oilfield services provider. Not only did the SPM™ EdgeX Carbide Seats last eight times longer than the previous seats, the SPM™ EdgeX Carbide Seats eliminated shattering risk and on-site seat replacements, unlike competitors’ seats. SPM™ EdgeX Carbide Seat reduced the total amount of time spent pulling seats by approximately 16 hours.

The operator ran the SPM™ EdgeX Carbide Seats an average of 655 hours—delivering approximately 720% longer life than steel seats that last an average of just 80 hours. One seat ran 760 hours—setting a record for the longest-lasting SPM™ EdgeX Seat in North America. Based on the longevity and reduced maintenance time, the operator plans to outfit an entire fleet with SPM™ EdgeX Carbide Seats.

SPM™ Oil & Gas’ patented SPM™ EdgeX Valve and Carbide Seat sets a new industry standard by increasing seat life an average of six times compared to conventional steel seats and doubling valve life. It is a timely solution for operators focused on pump utilization and reducing downtime for pump maintenance. Engineered with the nuances of the entire frac site in mind, the SPM™ EdgeX Valve and Carbide Seat enables operators to push their frac fleets harder while significantly reducing maintenance costs for valves and seats. This dramatic increase in longevity enables operators to eliminate field changeouts and reduce expenses for a costly consumable.

RELATED CASE STUDIES

LATEST NEWS

-

Saving NPT in Extreme Conditions

Oilfield companies require pressure pumping equipment that meets today’s rigorous demands and are paying closer attention to the longevity of parts on site. One of the top consumables, fluid ends, can directly impact the uptime of hydraulic fracturing pumps and support operational efficiency.

Learn More -

SPM™ WS 335 Frac Pump Surpasses 13,000 Pumping Hours in the Permian

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today an SPM™ WS 335 Frac Pump achieved more than 13,000 pumping hours in the Permian before its first overhaul.

Learn More -

Fluid Ends Engineered for the Oilfield Deliver a Competitive Advantage

Well services equipment must endure the toughest environments. Pressure pumping operators need reliable solutions and know their fleet is only as strong as its most sensitive components. Critical pump consumables such as fluid ends must be built to last no matter the operating conditions.

Learn More -

SPM™ Oil & Gas Launches On-Demand Oilfield Parts Availability in North America

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today a new streamlined platform to provide drilling and production expendables to customers and distributors. Oilfield parts can now be ordered on-demand across North America.

Learn More