AT A GLANCE

Constructed of tungsten carbide and stainless steel

Replaceable in the field

Compatible with any tapered fluid end

Resists shattering

Improves safety

Reduces NPT

THE FACTS

528 hours average run-time

797% longer seat life

500+ stages fraced

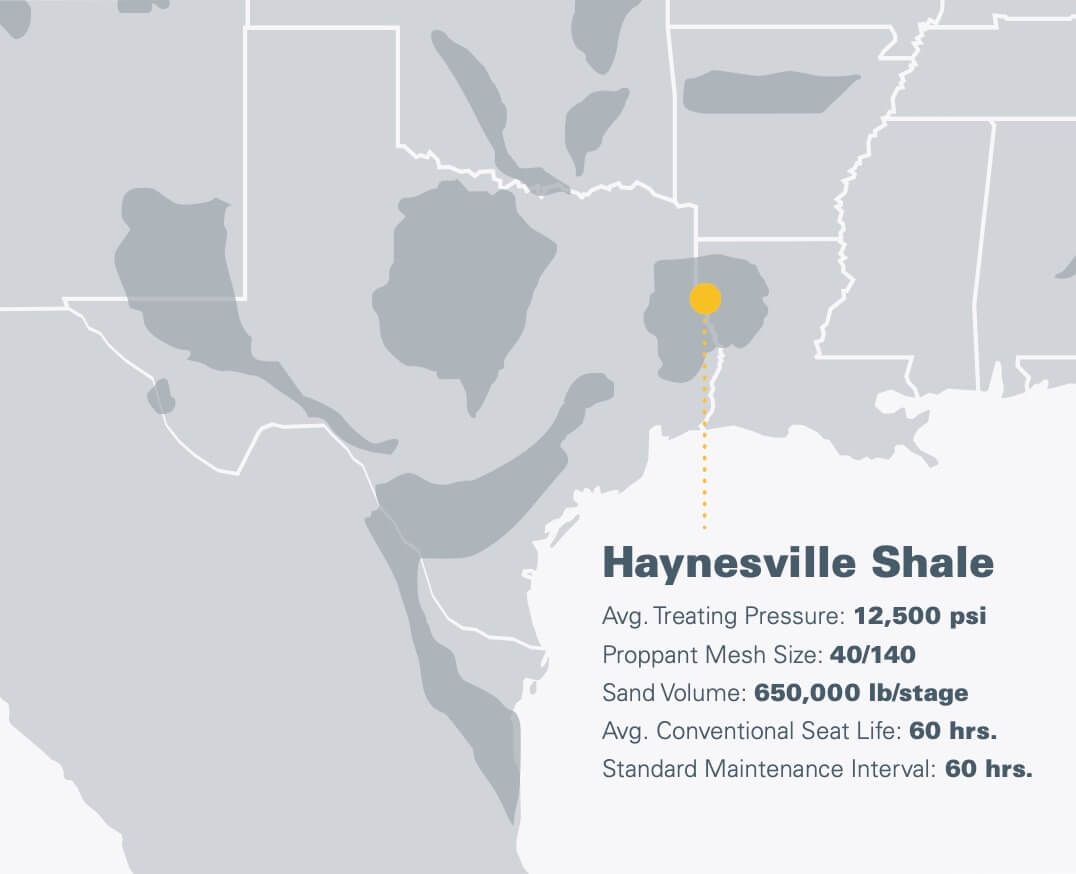

With treating pressures as high as 12,500 psi, the Haynesville Shale subjects frac equipment to some of the most extreme conditions of any play in North America. To complete its multiwell pads, a Haynesville operator pumped an average of 650,000 pounds of abrasive 40/140-mesh proppant per stage. Despite the challenging conditions, the SPM™ EdgeX Carbide Seat lasted an average of 538 hours—an increase of 797% compared with conventional steel seats.

The Haynesville Basin subjects frac equipment to the harshest conditions of any play in North America. As such, pumping operations in the Haynesville often bring shorter maintenance cycles and greater consumables expenses.

An oilfield services provider operating pumps in the Haynesville Basin wanted to achieve greater efficiencies by reducing the costs and nonproductive time (NPT) of its multiwell pad operations. Pumping up to 650,000 lb/stage of highly abrasive 40/140-mesh proppant at pressures up to 12,500 psi was causing its steel valve seats to fail prematurely. The operator had to implement a 60-hour maintenance cycle, resulting in significant materials and labor costs.

SPM™ Oil & Gas’ team installed SPM™ EdgeX Carbide Seats. With innovative tungsten carbide insert technology, the SPM™ EdgeX Carbide Seats resist wear, cracking, and washout while eliminating risk of the seat shattering, which could damage the fluid ends, or worse, cause a catastrophic pump failure. In addition, the SPM™ EdgeX Carbide Seats allowed the oilfield services company to use its existing tapered fluid ends and valves—giving it maximum operational flexibility.

Despite the 12,500-psi treating pressure and highly abrasive sand, the SPM™ EdgeX Carbide Seats lasted nearly nine times longer than the previous seats. The pumping provider ran the SPM™ EdgeX Carbide Seats an average of 538 hours—the longest life of any seat ever used by the company in the Haynesville Shale. Compared to the typical 60 hours of seat life, the SPM™ EdgeX Carbide Seats provided 797% longer life, dramatically reducing maintenance touches, nonproductive time, and risk of injury on site.

SPM™ Oil & Gas’ patented SPM™ EdgeX Valve and Carbide Seat sets a new industry standard by increasing seat life an average of six times compared to conventional steel seats and doubling valve life. It is a timely solution for operators focused on pump utilization and reducing downtime for pump maintenance. Engineered with the nuances of the entire frac site in mind, the SPM™ EdgeX Valve and Carbide Seat enables operators to push their frac fleets harder while significantly reducing maintenance costs for valves and seats. This dramatic increase in longevity enables operators to eliminate field changeouts and reduce expenses for a costly consumable.