AT A GLANCE

Service and training centers are no more than three hours from any U.S. basin

24/7 responsiveness

Only service center open in Williston during global pandemic

No rush fees

TOTAL SAVINGS

Prevented $100,000 loss of a pump

Reduced NPT and labor costs by providing on-site inspection and maintenance

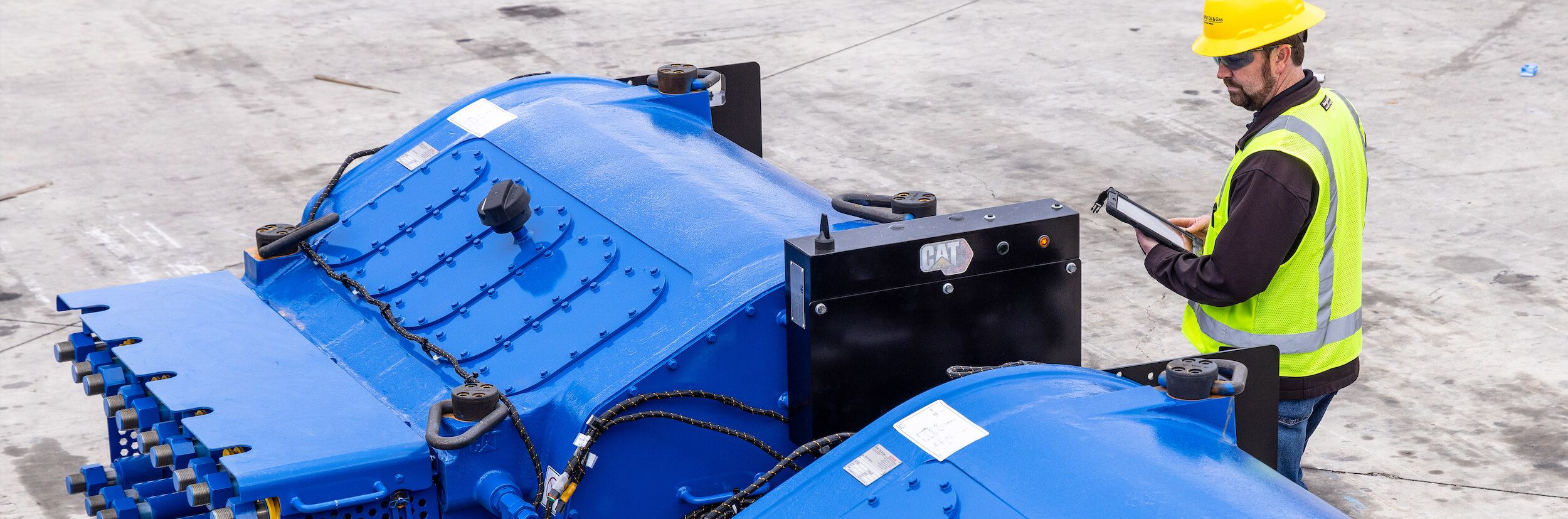

One of the largest oilfield services providers operating in the Bakken had a frac spread consisting of 14 to 20 pumps. Completing these wells economically meant no flexibility if a pump went down and no time for maintenance. The oilfield services provider required power end maintenance on one of its SPM™ QWS 2500 XL Frac Pumps, but couldn’t afford the NPT involved in powering it down or the labor costs to drive it to SPM™’s Williston Service Center when its personnel had already been reduced due to the global pandemic.

To provide critical pump maintenance with as little NPT as possible, SPM™’s Williston Service Center—the only service center open in the region during the global pandemic—brought the shop to the company’s frac site by dispatching a technician to conduct SPM™’s signature 13-point inspection process. After determining the extent of the maintenance required, the technician performed the necessary maintenance services and changed wearable components.

By performing inspection and maintenance on the frac site, the Williston SPM™ Edge Service Team saved the company significant NPT, equipment, and labor costs. The on-site visit saved the pump, preventing it from becoming a $100,000 loss. It also eliminated the downtime and labor costs involved in changing the pump and making the round trip to SPM™’s Williston Service Center—completely removing the burden of logistics from the company’s shoulders.

SPM™ Edge Services, SPM™’s’ global service offering, provides service and training centers in every U.S. basin and every part of the globe. SPM™ Edge Services supports operators with a three-pronged approach that includes global access to local engineering experts, engineered repairs with highly skilled aftermarket support, and industry-leading digital empowerment tools for SPM™ and other OEM equipment, all within a three-hour trip.

RELATED CASE STUDIES

LATEST NEWS

-

Saving NPT in Extreme Conditions

Oilfield companies require pressure pumping equipment that meets today’s rigorous demands and are paying closer attention to the longevity of parts on site. One of the top consumables, fluid ends, can directly impact the uptime of hydraulic fracturing pumps and support operational efficiency.

Learn More -

SPM™ WS 335 Frac Pump Surpasses 13,000 Pumping Hours in the Permian

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today an SPM™ WS 335 Frac Pump achieved more than 13,000 pumping hours in the Permian before its first overhaul.

Learn More -

Fluid Ends Engineered for the Oilfield Deliver a Competitive Advantage

Well services equipment must endure the toughest environments. Pressure pumping operators need reliable solutions and know their fleet is only as strong as its most sensitive components. Critical pump consumables such as fluid ends must be built to last no matter the operating conditions.

Learn More -

SPM™ Oil & Gas Launches On-Demand Oilfield Parts Availability in North America

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today a new streamlined platform to provide drilling and production expendables to customers and distributors. Oilfield parts can now be ordered on-demand across North America.

Learn More