ENGINEERED TO OVERCOME

Zero NPT pumping pressure

$1,000,000 in NPT savings cost

13,000 psi pumping pressure

2,000 Hours pumping in the fields

Overview

A service provider wanted to reduce pump-related NPT during hydraulic fracturing treatments in the Haynesville Shale. With extended pumping hours, 13,000-psi treating pressure, and poor sand quality, the company’s pumping equipment required above-average maintenance and downtime. Bringing the highest rod load in its class, the SPM™ EXL Frac Pump delivered zero NPT and enabled the operator to increase pumping hours despite the Haynesville’s harsh fracing conditions. With a fleet of SPM™ EXL Frac Pumps, the company is estimated to save an hour of pumping time per day—generating a cost savings of more than $1 million per fleet.

The Haynesville Shale has some of the most brutal fracing conditions of any unconventional play. Its low-quality in-basin sand and 13,000-psi treating pressure dramatically reduce equipment reliability and maintenance cycle times.

Pumps in the field regularly crack under the stress, gear sets wear down prematurely, and the fluid ends require significant repairs for damage. With 20 pumps—and 20 sets of expendables—to maintain, an oilfield services company in the Haynesville wanted to reduce its above-average nonproductive time (NPT), which was cutting into pumping hours and economics.

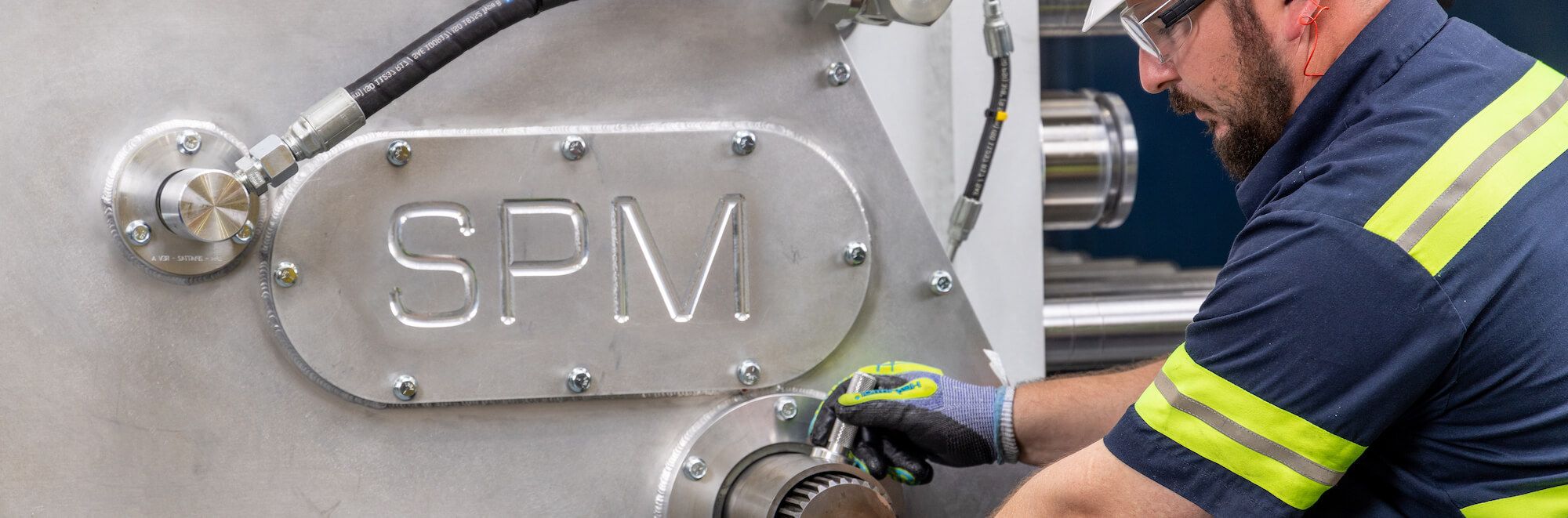

To increase pumping hours, the service company installed an SPM™ EXL Frac Pump to run with the rest of its fleet. In addition to reducing onsite maintenance, the flexibility and rod load capabilities of the SPM™ EXL Frac Pump eliminated the need for separate fleets for high- and low-pressure environments

Despite 18 to 22 hours of pumping time per day in Haynesville’s extreme environment, the service company experienced zero NPT throughout the test period. The SPM™ EXL Frac Pump logged over 2,000 hours while consistently pumping over 13,000 psi. It ran for more than 1,000 hours before it required maintenance and was the only pump on location to not get pulled due to reliability issues. Outfitted with a fleet of SPM™ EXL Frac Pumps, conservative estimates expect the company to save one hour of NPT per pumping day, for a cost savings of more than $1 million.

SPM™ Oil & Gas designed the high-performance frac pump to address the unique challenges of pressure pumping in extreme conditions. With fewer internal welds, a redesigned gear set, and a solid-steel unibody-nose plate, the SPM™ EXL Frac Pump delivered greater rigidity and reliability than traditional frac pumps. Featuring the SPM™ Everbore™ hardened steel packing bore, the new pump eliminates washboarding and the need to re-sleeve.

Increasingly brutal conditions, longer operating hours, less-frequent service intervals and limited field resources—these are the challenges that inspired SPM™ Oil & Gas to engineer the SPM™ EXL Frac Pump. With the highest rod-load rating in its class—238,000 lbf—it systematically addresses the biggest issues confronting operators and manufacturers.

LATEST NEWS

-

Saving NPT in Extreme Conditions

Oilfield companies require pressure pumping equipment that meets today’s rigorous demands and are paying closer attention to the longevity of parts on site. One of the top consumables, fluid ends, can directly impact the uptime of hydraulic fracturing pumps and support operational efficiency.

Learn More -

SPM™ WS 335 Frac Pump Surpasses 13,000 Pumping Hours in the Permian

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today an SPM™ WS 335 Frac Pump achieved more than 13,000 pumping hours in the Permian before its first overhaul.

Learn More -

Fluid Ends Engineered for the Oilfield Deliver a Competitive Advantage

Well services equipment must endure the toughest environments. Pressure pumping operators need reliable solutions and know their fleet is only as strong as its most sensitive components. Critical pump consumables such as fluid ends must be built to last no matter the operating conditions.

Learn More -

SPM™ Oil & Gas Launches On-Demand Oilfield Parts Availability in North America

SPM™ Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, announced today a new streamlined platform to provide drilling and production expendables to customers and distributors. Oilfield parts can now be ordered on-demand across North America.

Learn More