Breaking from Tradition

Linear Pressure Control Approach Reduces NPT, Costs and Safety Risks

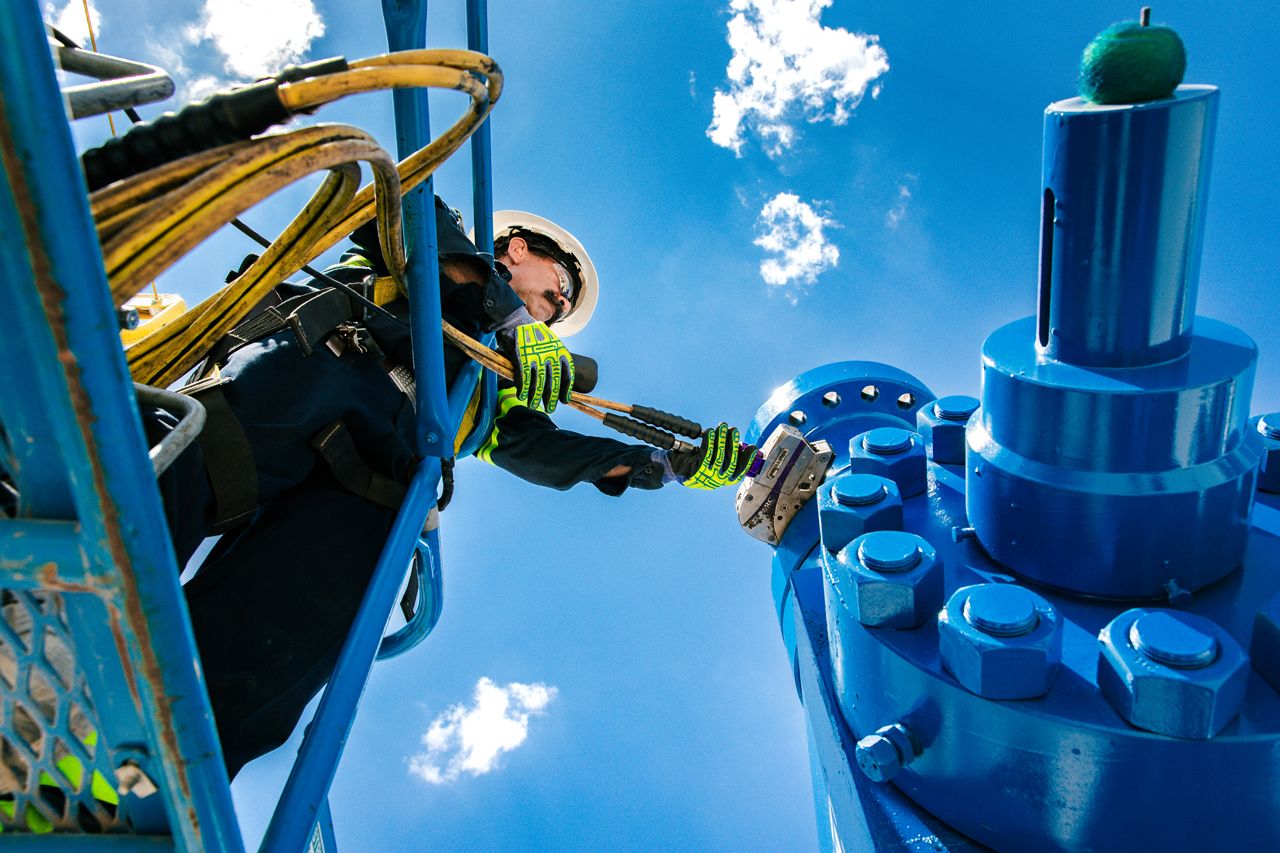

The traditional pressure-pumping location can appear rather chaotic with flow iron snaked in every direction, elbows and tees crisscrossing the pad and personnel weaving through a maze of trip hazards. Each threaded connection represents potential leaks and nonproductive time (NPT).

Below, SPM™ Oil & Gas' global pressure control experts address key questions around the evolution of pressure control and optimizing site efficiency – and how to do it all safely.

Why is the Industry Embracing an Alternative Flow Iron Approach?

Diverging from the traditional approach to flow iron began around mid 2010s in North America, when the shift from completing one well at a time to multi-well pads started to gain favor. Crews quickly discovered some limitations of deploying conventional flow iron in this new, efficiency-driven pad configuration.

Traditional 2-in. or 3-in. steel pipe encounters abrasive proppant, cyclic high-pressure fatigue, corrosion and chemically aggressive fracturing fluids. Each unplanned repair halts pumping, while every additional joint adds a potential leak path. Additionally, rental fleets often arrive with uneven maintenance histories which force operators to incur unplanned NPT for inspection and repair. This downtime can be exacerbated by parts availability.

Oilfield companies operating multi-well pads needed more than incremental improvements.

How Can Linear Pressure Control Optimize Operations?

Recognizing the need for a different method, SPM Oil & Gas developed complementary innovations that create a linear pressure control architecture. The SPM Large Bore system offers oversized bore diameters to carry full frac rates with lower velocity, reducing internal wear and extending iron life. It features pre-staged modular skids that enable a frac crew to seamlessly back in, hook up and pump. This promotes faster rig-up times and greater efficiency, accelerating pad-move cycles and increasing pumping time.

The SPM large bore frac tree and manifold is a manifold system that provides a simple linear flow line. It utilizes fewer connections which decreases potential leak paths, NPT and rig-up time. The manifold system also delivers a smaller wellsite footprint to increase on-site safety.

Together, these technologies create the linear pressure control layout that underpins simul-frac and continuous-pumping strategies. Where traditional setups required days of complex rigging with dozens of workers, linear configurations can be operational in hours with minimal crew requirements – removing 80% or more of the connections on location.

What Makes Continuous Pumping Achievable at Scale?

To maximize uptime beyond the linear configuration, SPM Oil & Gas leverages its latest gate valve technology designed to eliminate grease requirements during frac operations. This cost and time-saving enhancement can trim approximately $3,000 in consumables per valve per job in addition to roughly $2,500 per day in labor.

When combined with linear iron configurations, operators report total project cost reductions of 18 to 30%. The entire assembly is engineered for continuous pumping, empowering oilfield companies to pump over 20 hours per day; a key differentiator of top-quartile fleets. Staying online longer not only raises stage counts but also spreads fixed cost overhead across more pumped hours, compounding savings on every pad. The modular design of this linear approach easily accommodates the horsepower required for continuous operations.

Ultimately, the ability to reduce the time to complete a well from more than 30 days to just 14 days represents a 50% reduction in completion time – a transformation made possible by maintaining operations while performing maintenance activities.

Why Does Single-Source Support Matter in Complex Pressure Control Operations?

Pressure control performance relies on people and processes as much as iron and valves, which is why SPM Oil & Gas' single-source capabilities make a difference in the field. The approach combines engineering, rental, field service and project manager "concierge" support – eliminating the coordination gaps that can arise when relying on multiple vendors.

This integrated support structure has enabled important operational achievements:

- Rig-ups and rig downs are completed in 24 hours or less (compared to the traditional two-day standard).

- Pre-planning and advanced installation of equipment allow frac pumps to arrive on location, make a single connection and start pumping.

- Two-day turnaround times between pads when fleet schedules tighten.

- Seamless transitions that keep the most expensive asset – the frac crew – productive.

- Flexible operations support and equipment setup that adapts to changing operational requirements from pad to pad.

Unlike other approaches that typically require a two-step process (order taking and execution), SPM Oil & Gas adds a dedicated support layer that acts as a concierge service. This project manager support enables rapid response to field changes and ensures consistency across the entire pressure control system.

Are Global Markets Adopting Linear Pressure Control?

The linear pressure control revolution is extending beyond North American basins to oilfields in North Africa, the Middle East and China. Eastern Hemisphere operators are increasingly adopting these solutions to address their own operational challenges, from unconventional gas completions operations to remote desert locations.

The Road Ahead: From Cutting Edge to Baseline

With large E&Ps embracing providers who can support linear continuous-pumping operations, what was once considered cutting edge is fast becoming the baseline. Oilfield companies increasingly require strategic collaborators capable of executing complex, efficiency-driven configurations.

Linear pressure control is field proven to lower NPT, cut total well costs and reduce on-site safety risks. The technology continues evolving toward greater automation, with SPM Oil & Gas developing solutions that will enable remote operation from frac data vans – further removing personnel from high-risk environments while eliminating transition time and human error.

For oilfield companies determined to increase frac pad efficiencies, the fastest path forward is a straight line.